Walk into a beautifully preserved period property, and chances are you're looking at walls finished with lime plaster. At its core, it’s a beautifully simple, traditional wall covering made from just three things: lime, sand, and water.

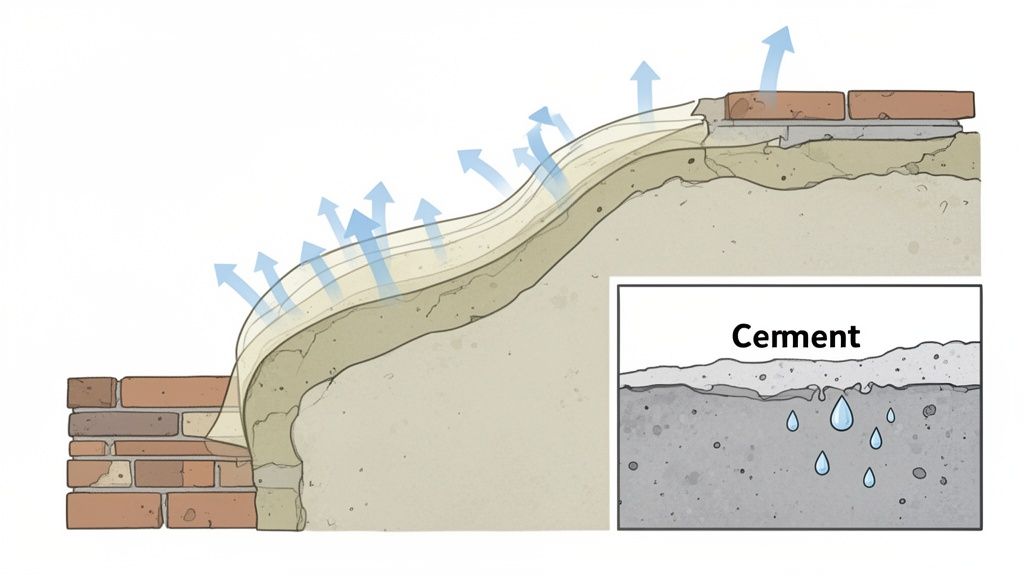

But to call it just a "wall covering" is to miss the point entirely. Think of lime plaster as a breathable skin for your home's walls. It’s designed to let moisture pass through it, rather than trapping it inside – a crucial function for keeping older buildings healthy and dry. This is a world away from modern materials that often seal a wall up tight.

The Secret to Healthy Historic Homes

Imagine your home’s walls need to breathe, just like you do. That’s the easiest way to understand what lime plaster is and why it's absolutely vital for period properties. Unlike modern cement or gypsum-based plasters that act like an impermeable plastic raincoat, lime plaster behaves more like a high-performance Gore-Tex jacket.

This clever "jacket" allows moisture vapour—from cooking, showering, and even our own breath—to pass harmlessly through the wall and evaporate away. Modern materials, on the other hand, trap this moisture deep inside the wall's structure. Over time, that trapped damp can lead to disaster: timber rot, black mould, and crumbling brickwork that causes serious damage to the building's fabric.

The Power of Natural Components

The real magic of lime plaster lies in its simple, natural recipe. The lime is the binder, the sand gives it bulk and strength, and the water makes it all workable. Together, they create a material that is both incredibly durable and surprisingly forgiving.

This natural flexibility allows it to accommodate the tiny, constant movements of an older building without cracking. That’s a common failure point for rigid modern plasters, which often just can't cope with the subtle shifts of a historic structure.

A few key benefits come directly from these components:

- Vapour Permeability: It actively helps manage humidity levels inside the home, leading to better air quality and preventing damp problems before they start.

- Flexibility: It moves with the building, which means far fewer of those ugly stress cracks appearing on your walls.

- Sustainability: Made from abundant natural materials, it has a lower carbon footprint than cement production and can even be recycled.

Lime plaster doesn't just sit on a wall; it works in harmony with it. Its ability to manage moisture is the single most important factor in preserving the structural integrity and unique character of historic homes.

Lime Plaster at a Glance

To make the distinction even clearer, let’s put its core features head-to-head with modern plasters. This quick comparison shows exactly why choosing the right material is so crucial for the long-term health of your property.

| Characteristic | Lime Plaster | Modern Plaster (Cement/Gypsum) |

|---|---|---|

| Breathability | High (Vapour Permeable) | Low (Vapour Impermeable) |

| Flexibility | High (Accommodates Movement) | Low (Rigid and Brittle) |

| Moisture Handling | Manages Humidity | Traps Moisture |

| Sustainability | Low Carbon Footprint | High Carbon Footprint |

| Repairability | Simple and Seamless | Difficult to Patch |

As you can see, the two materials are fundamentally different. For a period property, especially in a climate like the UK's, the choice has a huge impact on everything from indoor air quality to the building's very survival.

The Enduring Legacy of Lime Plaster in Historic Buildings

Lime plaster is so much more than a building material; it's a piece of living history tucked away inside the walls of our most treasured period homes. When you walk through a Victorian terrace or an Edwardian semi in London, you're moving past surfaces crafted with techniques handed down through generations. This is what connects a modern home to its historical soul.

From grand medieval cathedrals to the classic houses that define so many British streets, lime plaster was the go-to material for centuries. And that was no accident. Early builders knew its unique properties—a blend of durability, flexibility, and breathability—were a perfect match for the solid-walled construction methods of the time. This deep understanding of how materials work together is a form of craftsmanship we now fight to preserve.

The Art of Lath and Plaster

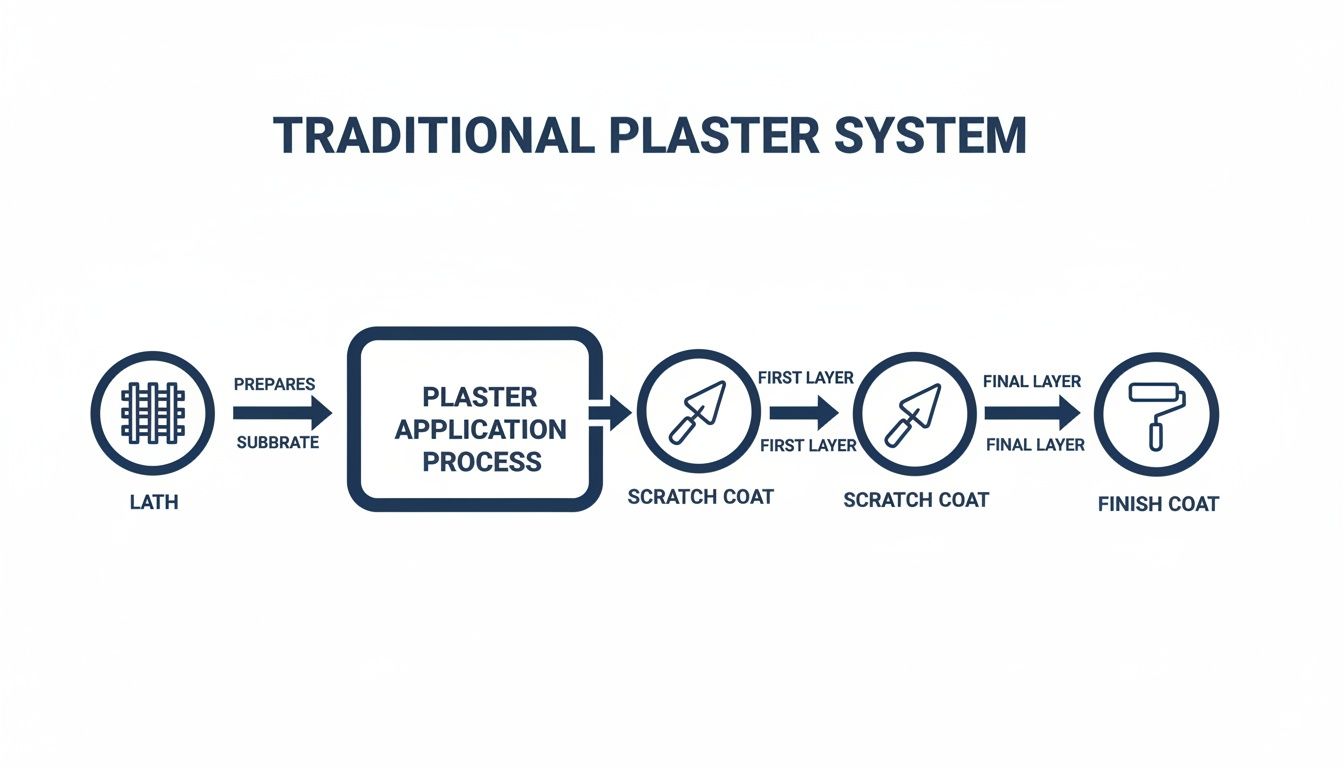

To really get what lime plaster is all about, you have to understand how it was traditionally applied. The most common method you'll find in period properties is the lath and plaster system, a meticulous, multi-layered process that created astonishingly tough walls and ceilings.

This wasn't just a case of slapping on a single coat. Craftsmen built up the surface in distinct stages, with each one playing a critical role:

- The Laths: First, thin, hand-split strips of wood called laths were nailed horizontally across the timber frame, leaving small gaps between them. This wooden grid created the essential framework for the plaster to grab onto.

- The Scratch Coat: The first layer of coarse lime plaster was then pushed on with real force, forcing it through the gaps in the laths. As it oozed through, it would droop and harden on the other side, forming "nibs" that locked the plaster securely to the frame. The surface was then scratched up to give the next layer something rough to stick to.

- The Brown Coat: Also known as the floating coat, this was a thicker layer that went over the scratch coat to build up depth and create a flat, even surface. This is where the wall got most of its strength and insulation.

- The Finish Coat: Finally, a very thin, smooth top coat of fine lime plaster was meticulously trowelled on. This layer gave the wall its beautiful, soft finish, ready for paint or paper.

This layered system created a wall that was more than just a surface; it was a dynamic, integrated structure. It was strong, yet flexible enough to move with the building as it settled over time.

A Heritage Rooted in British Architecture

The use of lime plaster has been a cornerstone of British architecture for hundreds of years. It was particularly vital in England, where it formed the backbone of lath and plaster systems from the 15th century onwards. Since the "Lime Revival" kicked off in the early 2000s, there's been a renewed appreciation for this heritage. Reports suggest that over 5,000 heritage sites in the UK have had their original lime plaster reinstated.

Understanding this historical context is everything. It explains precisely why modern, rigid materials like cement or gypsum-based plasters often fail spectacularly in older homes. They are fundamentally incompatible with how these buildings were designed to breathe and move. They trap moisture, introduce stress, and ultimately damage the very structure they're meant to protect.

Restoring lime plaster isn't just a repair job; it's an act of genuine heritage conservation. It requires a specialist skillset to honour the craftsmanship of the past. If you're considering a project like this, getting your head around the nuances of period property renovations is the first, most crucial step.

Getting to Grips With Different Types of Lime Plaster

Picking the right lime plaster isn't just a technicality; it's a decision that directly affects the health of your walls. Think of it like choosing the right fabric. You wouldn't wear a heavy wool coat in summer, and you can’t just slap any old plaster onto a wall without knowing what it needs.

The world of lime plaster is split into two main families: Non-Hydraulic Lime and Hydraulic Lime. Understanding how they work is the key to getting it right for your property. They set, or cure, in completely different ways, which gives them unique strengths and uses.

The Gentle Breathability of Non-Hydraulic Lime

Often called fat lime putty or simply lime putty, non-hydraulic lime is the purest form you can get. It sets through a slow, gentle process called carbonation, where it pulls carbon dioxide from the air to harden over time. This isn't a quick job—it can take weeks, or even months, to fully cure.

Think of it like a soft, natural linen. It's incredibly breathable, flexible, and gentle on the building. This makes it the perfect choice for internal plasterwork in older, solid-walled properties where managing moisture in the air is a top priority. Its softness allows it to move with the subtle shifts of a historic building without cracking.

- Best Use: Internal walls and ceilings in historic buildings.

- Key Trait: Maximum vapour permeability (the best breathability).

- Setting Process: Sets slowly by exposure to air (carbonation).

This gentle nature, however, means it's not cut out for external jobs or damp areas where it would be exposed to the elements before it's had a chance to properly harden.

The diagram below shows the traditional layered approach where these kinds of plasters really shine.

This process, from the structural lath to the smooth finish, was perfected for materials like non-hydraulic lime that need to be built up carefully.

The Robust Durability of Hydraulic Lime

In contrast, hydraulic lime has natural impurities like clays mixed in. These allow it to set with water, a process known as hydrolysis. It’s much faster and results in a stronger, harder finish—a bit like modern cement, but without blocking the wall's ability to breathe.

If non-hydraulic lime is linen, think of hydraulic lime as a durable, weather-resistant material like waxed cotton. It’s stronger and cures faster, making it the go-to for external rendering or for internal spots prone to damp, like basements or kitchens. This makes it particularly good for jobs like pointing and rendering on Victorian houses, which have to stand up to the British weather.

Hydraulic lime offers a practical balance. It provides a faster, more robust set suitable for challenging conditions while still retaining the essential breathability that period properties need to stay healthy.

Decoding the NHL Grades

Hydraulic limes are sorted into grades called Natural Hydraulic Lime (NHL). These grades tell you the lime's strength and how fast it sets, letting a specialist pick the perfect mix for the job. The scale is simple: the higher the number, the stronger and faster-setting the lime.

| NHL Grade | Compressive Strength (After 28 Days) | Best For |

|---|---|---|

| NHL 2 | Soft and highly flexible | Internal plaster on soft or crumbly old backgrounds. |

| NHL 3.5 | Moderately strong | A great general-purpose choice for internal and external work. |

| NHL 5 | Strongest and most durable | External rendering, chimney pointing, and stonework. |

Getting these grades right is vital. Using a lime that’s too strong on a soft, historic brick can cause serious damage, as the plaster ends up being harder than the brick itself. A good plasterer will assess the wall and its exposure to the elements to choose the correct NHL grade, ensuring the new plaster works with the building, not against it.

Why Lime Plaster Is Superior to Modern Alternatives

When you're picking a finish for the walls in a period property, the choice between traditional lime plaster and modern stuff like cement or gypsum isn't just about looks. It's about the long-term health and survival of the building itself. While modern materials promise a quick, flawless finish, they're fundamentally at odds with how older buildings are designed to work. Lime plaster, on the other hand, works in perfect harmony with historic structures.

The heart of it all comes down to one critical word: breathability. Think of your home's walls needing to breathe in and out. Lime plaster is vapour-permeable, meaning it lets moisture from everyday life—cooking, showering, even just breathing—pass straight through the wall and evaporate away. This simple process stops damp from getting trapped inside the building's structure.

The Problem with Trapped Moisture

Modern plasters, especially those made with cement and gypsum, act like a plastic sheet wrapped around your walls. They create a hard, sealed surface, but they also trap any moisture that gets into the wall, whether it's from inside the house or from damp penetrating from outside.

This trapped moisture is the root cause of so many serious problems we see in older properties. It can lead to:

- Timber Decay: Structural timbers like joists and lintels start to rot when they're stuck in constantly damp conditions.

- Mould and Mildew: Trapped moisture is the perfect breeding ground for mould, which doesn't just ruin your plaster and paint but is also a serious health risk.

- Brick and Stonework Damage: In winter, trapped water freezes and expands—a process called frost spalling—which can literally blow the faces off bricks and stone, causing them to crumble.

By sealing the walls, modern materials effectively suffocate a building that was designed to breathe, often causing far more damage than whatever problem they were meant to fix.

Natural Flexibility and Self-Healing Properties

Beyond its breathability, lime plaster has a remarkable natural flexibility. Older buildings aren't static; they shift and move subtly with the seasons as temperature and humidity change. Rigid cement and gypsum plasters just can't handle this movement, which leads to stress fractures and ugly cracks.

Lime plaster is softer and more elastic, so it can flex along with the building. This natural give massively reduces the chances of cracking. Even more impressively, lime has a unique ability to self-heal. When tiny cracks appear, any moisture that gets in can reactivate the "free lime" in the plaster, letting it re-crystallise and literally seal the gap.

This self-healing characteristic is one of lime plaster's most powerful, yet least understood, benefits. It’s an active material that works continuously to maintain its own integrity, something a static, brittle cement plaster simply cannot do.

This means walls finished in lime aren't just healthier; they're also tougher and need less maintenance over their lifetime.

The Sustainable and Healthy Choice

The benefits don't stop there. Choosing lime is also a great move for the environment and your health. Making lime uses a lot less energy than producing cement, so it has a much lower carbon footprint. As it slowly cures (a process called carbonation), lime plaster actually re-absorbs carbon dioxide from the atmosphere, partially cancelling out its initial production emissions.

On top of that, lime is a natural material with a high pH, making it inherently anti-bacterial and resistant to mould growth without needing any chemical nasties. This helps create better indoor air quality and a healthier living environment for you and your family. And at the end of its very long life, lime plaster can simply be crushed and recycled, often as a conditioner for agricultural soil.

Lime vs Cement vs Gypsum: A Head-to-Head Comparison

To really see the difference, it helps to put these materials side-by-side. The comparison below makes it pretty clear why lime is the only sensible choice for preserving the health and value of a period property. Investing in lime plaster isn't just a repair; it’s a long-term commitment to your home's wellbeing.

| Feature | Lime Plaster | Cement Plaster | Gypsum Plaster |

|---|---|---|---|

| Breathability | Excellent (Vapour Permeable) Lets walls breathe naturally. | Very Poor (Impermeable) Traps moisture inside the wall. | Poor (Low Permeability) Can trap moisture, causing damp. |

| Flexibility | High Moves with the building to prevent cracks. | Very Low (Rigid) Cracks easily under structural stress. | Low (Brittle) Prone to cracking and chipping. |

| Durability | Extremely High Lasts for centuries and self-heals. | High Strength but Brittle Can damage softer historic brickwork. | Moderate Not suitable for damp or external areas. |

| Sustainability | High Lower carbon footprint and recyclable. | Very Low Energy-intensive production process. | Low Often contains synthetic additives. |

| Health Impact | Positive Naturally anti-bacterial and regulates humidity. | Neutral Can contribute to damp-related mould. | Negative May contain VOCs and trap damp. |

When you look at the evidence, the choice becomes obvious. Modern plasters might offer a quick fix, but for a building that has stood for generations, only lime offers the gentle, breathable protection it needs to stand for many more.

How to Spot and Deal With Damaged Lime Plaster

Even the toughest lime plaster can start to show its age after a century or two. Learning how to spot the early warning signs is the key to stopping small issues from turning into big, expensive headaches. This guide will help you read the signals your walls are sending and understand the right way to go about restoration.

Honestly, learning to read your walls is a vital skill for any owner of a period home. Many problems that look purely cosmetic are actually symptoms of deeper issues, usually related to moisture or structural movement. If you ignore them, the root cause just gets worse, potentially leading to much more serious damage down the line.

Common Signs of Plaster Failure

Keep an eye out for a few distinct clues that your plaster is in distress. Each one tells a different story about what’s happening inside your wall. Catching them early means you can get a targeted, effective repair that respects your home’s original fabric.

You might notice one or more of these common issues:

- Hollow Sounds: Give the plaster a gentle tap. If you hear a dull, hollow thud instead of a solid knock, it means the plaster has pulled away from the lath or brickwork behind it. This is a classic problem known as bossing or delamination.

- Sprawling Cracks: Fine hairline cracks can be perfectly normal as a house settles. But if you see large, map-like cracks spreading across the wall, it often points to significant movement or stress. This could be the plaster itself failing or a sign of a more serious structural problem.

- Damp Patches and Staining: Are there persistent damp patches, discolouration, or a 'tide mark' on the plaster? These are clear signs that moisture is trapped in the wall, whether from penetrating damp, rising damp, or a hidden leak.

- Powdery or Crumbling Surfaces: If the plaster feels soft, powdery, or crumbles when you touch it, the lime binder that holds it all together has started to break down. This is almost always caused by long-term damp, which slowly degrades the material's strength.

The Dangers of Modern DIY Fixes

When you’re faced with a crack or a crumbling patch, it’s so tempting to just grab a tub of modern filler from the local DIY shop. But using cement-based patches or acrylic fillers on lime plaster is one of the worst mistakes you can make. It’s like putting a rigid plastic patch on a flexible cotton shirt—it just doesn’t work with the original material.

These modern fillers are impermeable. When you slap them onto a breathable lime wall, you create isolated spots that trap moisture. Water vapour that could once escape freely now hits a dead end, concentrating damp in the surrounding plaster and making the whole problem worse.

Using modern fillers on a lime plaster wall creates an impermeable barrier. This traps moisture, introduces new stress points, and accelerates the decay of the surrounding historic material, ultimately causing more damage than it solves.

This approach also creates new stress points. The rigid patch can't move and flex with the lime plaster around it as the building naturally shifts. Before you know it, new cracks start forming around the repair, leading to a frustrating cycle of patching and cracking that never gets to the root of the issue.

The Professional Restoration Process

Fixing damaged lime plaster properly requires a professional who genuinely understands traditional building methods. The process is careful and methodical, ensuring the repair is compatible with the existing structure and will last for decades to come.

A specialist will typically follow these key steps:

- Careful Removal: Any failed, loose, or crumbling plaster is gently removed back to a solid background. They take great care not to damage the underlying lath or brickwork in the process.

- Surface Preparation: The background is cleaned of all dust and debris and then dampened. This controls suction, ensuring the new plaster sticks properly without drying out too quickly, which would make it weak.

- Layered Application: New, compatible lime plaster is applied in thin layers, just as it would have been originally. This usually involves a 'scratch coat', a 'float coat' to build up the depth, and a fine finish coat for a seamless surface.

- Slow Curing: Each layer is given time to cure slowly through carbonation. This gradual hardening process is absolutely essential for building the strength and durability that define a proper lime plaster repair.

This meticulous approach ensures the repaired section breathes and flexes in harmony with the rest of the wall, preserving both the structural health and the unique character of your period home.

Finding the Right Professional for Your Lime Plastering Project

Choosing the right specialist for a lime plastering job is every bit as important as picking the correct material. Seriously. The success of your whole project hinges on the skill of the person applying it, because a bad technique can completely undo all the benefits of this amazing material.

An experienced professional gets that working with lime is a slow, methodical process—not a quick plaster-and-paint job. Unlike modern plastering where speed is often the main goal, traditional lime work demands a real appreciation for heritage building methods. A true specialist doesn't just slap plaster on a wall; they diagnose what your walls need, understanding the unique moisture profile and movement of a period property.

Key Credentials to Look For

Trying to find a qualified contractor can feel a bit overwhelming, but if you focus on a few key things, you'll soon spot the genuine experts from the crowd. You need to see real proof that they have the specialist skills required for older homes.

Your checklist should include these essentials:

- Proven Heritage Experience: Ask to see a portfolio of their work on period properties like yours. You’re looking for seamless repairs and finishes that respect the building’s original character.

- Deep Material Knowledge: A good plasterer should be able to confidently tell you why they’re recommending a specific type of lime—whether it's a fat lime putty or a particular NHL grade—for different parts of your home.

- Understanding of Breathability: They should talk passionately about vapour permeability and be able to clearly explain the dangers of using modern, sealed materials on an old building.

This level of expertise is what separates a heritage specialist from a general plasterer. For more detailed guidance on what to expect, you can learn about the high standards required for a professional plasterer in London who regularly works on historic homes.

Setting Realistic Expectations for Cost and Timelines

It’s really important to go into a lime plastering project with your eyes open about the investment needed. Both the materials and the specialist labour cost more than their modern equivalents. This isn't an upsell; it’s a reflection of the higher quality materials and the significant time and skill involved.

A professional lime plasterer isn't just a tradesperson; they are a custodian of heritage building techniques. The higher upfront cost is an investment in your property's long-term structural health, character, and value.

The process is also naturally slower. Lime plaster has to be applied in thin layers, and it needs proper time to cure between each coat. It's a process that just can't be rushed. A qualified contractor will build this curing time into their project plan and be totally transparent about the timeline from the very beginning.

Essential Questions to Ask Your Contractor

Before you commit to anyone, have a proper chat with potential contractors. Their answers will tell you a lot about their expertise and professionalism, giving you the confidence to move forward.

Come prepared with a list of direct questions:

- What is your specific experience with lime plaster in period properties?

- Which type of lime do you propose for my project, and why?

- How will you protect the rest of my property during the work?

- Are you fully insured for this type of specialised work?

- How will you communicate progress and any potential issues?

Choosing the right partner for the job ensures your investment doesn't just restore the beauty of your walls but also protects the health and integrity of your home for generations to come.

Got Questions About Lime Plaster?

Even when you understand the basics, the practical side of lime plastering can bring up a few questions. It’s totally normal. Here are the straight answers to the things homeowners most often ask us, helping you get a clearer picture for your own project.

We'll cover everything from drying times to decorating, so you know exactly what to expect.

How Long Does Lime Plaster Take to Dry and Cure?

This is probably the biggest shift in mindset you'll need when moving from modern to traditional materials. Gypsum plaster might be ready for paint in just a few days, but lime demands patience. It’ll feel firm to the touch within a few days to a week, but that’s just the beginning.

The real magic is in the curing, a process called carbonation. For a typical three-coat job, you should give it at least a month to cure properly before you even think about painting. This slow, steady process is what gives the plaster its incredible strength and breathability. Rushing it will only weaken the finish.

Can You Paint Directly onto New Lime Plaster?

Absolutely, but—and this is a big but—you have to use the right paint. Slapping a coat of standard emulsion on a new lime wall is a disaster. It essentially wraps your wall in a plastic film, trapping moisture and completely undoing all the good work of using a breathable material in the first place.

You need to stick with vapour-permeable or "breathable" paints. Your best bets are:

- Limewash: The traditional choice. It's a thin paint made from lime and water that creates a chemical bond with the plaster.

- Clay-based paints: These offer a gorgeous, chalky matt finish and are just as breathable.

- Mineral paints: Silicate-based paints are another excellent option that allows the wall to breathe freely.

Is Lime Plaster More Expensive Than Modern Plaster?

Honestly, yes. The upfront cost for a lime plastering project is higher than using regular gypsum. There are two simple reasons for this: the specialist lime products themselves cost more, and you need a plasterer with genuine heritage skills to apply it properly—which costs more than a standard plasterer.

Don't just look at the initial bill, though. Think of lime plaster as a long-term investment in your home's health. It protects the very fabric of the building and stops damp problems before they start, saving you a fortune on repairs down the line and adding real value to your property.

How Do You Clean and Maintain Lime Plaster Walls?

Looking after lime plaster is surprisingly easy. For everyday dust, a quick once-over with a soft brush or a dry cloth is all you need. If you get minor scuffs or marks, you can usually clean them off gently with a damp sponge and a tiny bit of mild, pH-neutral soap.

Just be sure to avoid harsh chemical cleaners or anything abrasive, as they can easily damage the soft finish. The real beauty of lime is how simple it is to repair; a professional can seamlessly fill small cracks with a bit of matching lime putty, leaving no trace.

If you’re ready to bring back the authentic character and health of your period property with lime plaster, the team at All Well Property Services has the specialist skills to get it right. Get in touch today to talk about your project and receive a detailed quote.